Laboratory Ovens

To keep a muffle in good condition, it is important to check the insulation lining periodically. If the insulation lining is damaged, it must be replaced. If the damage is very severe, the oven may need to be replaced.

The furnaces are constructed of stainless steel and are kept at a stable temperature by using a temperature regulator. Most oven models also have a vacuum valve that is used to draw air out of the oven's interior to maintain an inert atmosphere.

They are used in a wide variety of applications, including glass making, ceramic curing and metal heat treatment. The maintenance of Mufflas ovens is very important to ensure their proper functioning. The following are some of the care you should be taking:

Types of Laboratory Stoves a Laboratory May Need

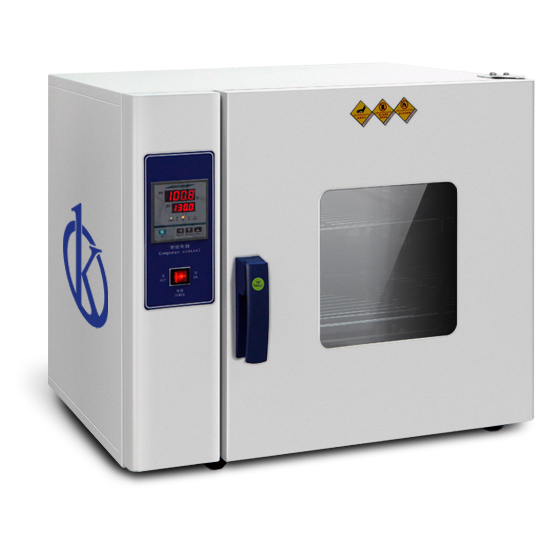

Industrial oven

These ovens allow the use of heat at high temperatures in a progressive manner. They are equipment designed to optimize the response time, stability and temperature uniformity. Forced air from the heating system heats the air and uses a fan to push the air around the ducts or chamber. They have an approximate accuracy of ± 0.5°C and the time in which it stabilizes is calculated between 25 minutes and 40 minutes. This can also vary due to the volume of material inside the equipment and the size of the chamber.

Forced convection allows for rapid drying and heating, temperature uniformity, and rapid temperature recovery after the cabinet door is opened. They have a temperature range from room temperature ±5 °C to 250 °C. This type of oven is regularly used in applications where very rigorous temperature precision is required, since its internal temperature can be exceeded by thermal inertia by up to 2°C. They are used in operations such as the drying of materials, dehydration of substances sensitive to sudden changes in temperature or that could be damaged by overheating, industrial process control for quality and highly explosive areas.

Vacuum ovens

- Interior chamber use streamlines arc design, the outer is made of cold-rolled steel plate, the surface uses the electrostatic spray.

- Liner is made of stainless steel or cold rolled material, easy to clean because of corners semicircular.

- The door’s elastic of the oven can be adjusted by the customer.

- Overall shape of the silicone rubber door seal to ensure a high vacuum oven, control panel with microcomputer control, solenoid control vacuum valve switch.

- With time and over-temperature alarm function, the door uses double glass, so the articles in Inner can be watche

In Kalstein you can find the Ideal Ovens for your Laboratory

Double Door Industrial Air Drying Oven

Double layer door; Microcomputer intelligent temperature control, digital display; centrifugal wind wheel...

Electric heating drying oven YR05244

Microcomputer intelligent PID control, precision LED display temperature control, timing, over-temperature...

Electric heating drying oven YR05248

Micro-computer intelligent control, temperature control, timing, over-temperature alarm function; fan forced...

Single Door Industrial Air Drying Oven

Microcomputer intelligent temperature control, digital display; centrifugal wind wheel, heat flow evenly; large...

Our Best Selling Ovens

Vacuum drying oven widely used in biochemical, chemical, pharmaceutical, health care, agricultural research, environmental protection and other research applications for powder drying and roasting,as well as disinfection and sterilization of glass containers used. Particularly suitable for drying heat-sensitive, easily decomposed, and the complex composition of easily oxidized material items for fast and efficient drying.

A variety of complex mechanical components or other porous samples after cleaning using a vacuum drying method, completely dry without leaving any residual material.

| Model | YR05260 (A) | YR05262 (SS) | YR05261 (A) | YR05263 (SS) | YR05264 (A) | YR05265 (SS) |

| Supply Voltage | 220 | |||||

| Temp. Range (°C) | RT + 5 ~ 250 | |||||

| Timer Range | 0 ~ 999 min | |||||

| Material | Zinc Plating Chamber | Stainless Steel | Zinc Plating Chamber | Stainless Steel | Zinc Plating Chamber | Stainless Steel |

| Temp. Accuracy | ± 1 | |||||

| Temp. Fluctuation (%) | ± 2 | |||||

| Power (KW) | 0.9 | 1.4 | ||||

| Vacuum Degree | < 133 | |||||

| Inner Size (mm) (H x W x D) | 28 x 30 x 30 | 40 x 41.5 x 35 | 44 x 48.5 x 42.5 | |||

Analysis of the best Ovens for your Laboratory

Laboratory ovens: Types and uses

Laboratory ovens are equipment used to dry and sterilize different laboratory materials and instruments...

Importance of a drying oven in a laboratory

Currently there are many types of laboratory equipment and instruments, but one of the most common and...

Stoves: dry heat sterilization

Hot air is one of the most widely used dry heat sterilization methods. This process is carried out in stoves, which allow the uniform distribution of heat inside ...

Drying ovens or ovens: Are they sterilizers?

The stove or also called drying oven is a piece of equipment used to dry and sterilize glass and metal containers...

Catalog of models of Ovens on offer

-

Vacuum Drying Oven YR05265-1 (SS) // YR05995 (S)

Select options This product has multiple variants. The options may be chosen on the product page -

Vacuum drying oven YR05260 (A) // YR05261 (A) // YR05264 (A)

Select options This product has multiple variants. The options may be chosen on the product page -

Double Door Industrial Air Drying Oven YR05257-1 // YR05259-1

Select options This product has multiple variants. The options may be chosen on the product page -

Single Door Industrial Air Drying Oven YR05256 // YR05258

Select options This product has multiple variants. The options may be chosen on the product page

Guides to become an expert in Ovens

What are the uses of a stove or oven in a laboratory?

It is a device used in the laboratory, to sterilize and dry glass or metal containers, removing all moisture from the containers...

Is laboratory oven the same as a laboratory oven?

Laboratory stoves or also called laboratory ovens are equipment that is used to dry and sterilize different materials...

Laboratory stoves and muffles: What are the differences ?

It is an essential equipment in laboratories and is also known as drying oven; is used for drying and sterilizing glass...

What are the differences between Drying Ovens, Muffle Ovens and Laboratory Incubators?

Within the laboratory and industrial sectors, there is a wide variety of furnaces of different types, which adapt to the applications they require, and their uses will depend on the maximum temperature at which they wish to work...

Frequently asked questions about Ovens from our customers

How to know the prices of Ovens?

To know the price of the Ovens we invite you to send us an email with your request through the contact form.

What are the delivery times of the Ovens?

- If the equipment of your interest is in stock or if it must be manufactured.

- The type of freight you have chosen, this may be; air or sea.

How to make a purchase of Ovens?

- By email: sales@kalstein.eu

- By telephone: +33 (0) 1 78 95 87 02

- E-commerce: Via Kalstein's official website in your country.

How does the warranty work?

Can I request a quote online?

Of course, you can request a quote for the Kalstein team of your interest, directly from our official website. Once you have identified your preferred model, click HERE